Label the schematic of the autoclave with the correct descriptions – Embarking on a comprehensive exploration of autoclaves, this discourse delves into the intricacies of their components, operating procedures, safety precautions, and troubleshooting techniques. By providing a clear understanding of autoclave schematics, we aim to empower individuals with the knowledge necessary for their safe and effective utilization.

This discourse will elucidate the functions of essential autoclave components, including the chamber, lid, pressure gauge, safety valve, and steam generator. Furthermore, it will provide a step-by-step guide to operating an autoclave, ensuring proper sterilization techniques. Additionally, safety guidelines will be Artikeld to minimize risks associated with autoclave use.

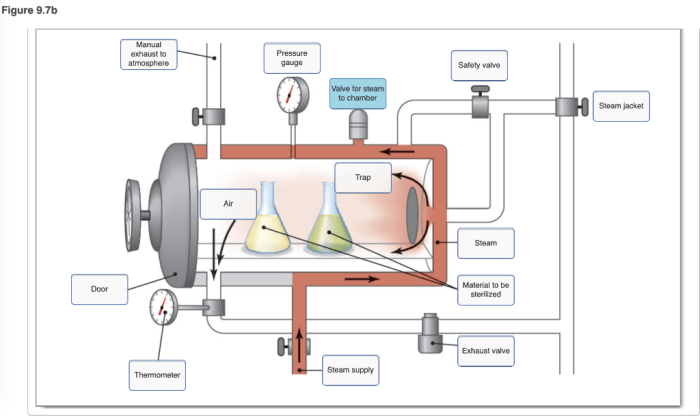

Components of an Autoclave: Label The Schematic Of The Autoclave With The Correct Descriptions

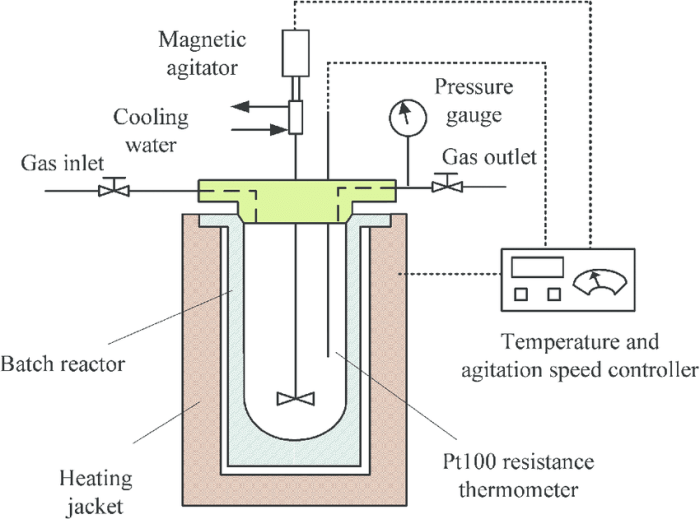

An autoclave is a device used to sterilize equipment and materials using high-pressure steam. It consists of several key components:

- Chamber:The chamber is the main compartment of the autoclave where the materials to be sterilized are placed.

- Lid:The lid seals the chamber to prevent steam from escaping during the sterilization cycle.

- Pressure gauge:The pressure gauge indicates the pressure inside the chamber, which is critical for maintaining the correct sterilization conditions.

- Safety valve:The safety valve releases excess pressure from the chamber if it exceeds a safe level.

- Steam generator:The steam generator produces the steam used to sterilize the materials.

Autoclave Operating Procedures

Operating an autoclave requires following specific procedures to ensure proper sterilization and safety:

- Loading the chamber:Materials to be sterilized are carefully loaded into the chamber, ensuring they are not overcrowded.

- Closing and sealing the lid:The lid is securely closed and sealed to create an airtight environment.

- Setting the temperature and pressure:The temperature and pressure settings are adjusted based on the sterilization requirements of the materials.

- Starting the sterilization cycle:The sterilization cycle is initiated, which involves heating the steam and maintaining the desired pressure and temperature.

- Monitoring the progress:The pressure gauge and temperature indicators are monitored to ensure the cycle is proceeding as intended.

- Unloading the chamber:Once the cycle is complete, the chamber is carefully opened and the sterilized materials are removed.

Safety Precautions for Autoclave Use

To ensure safe operation of an autoclave, several precautions must be followed:

- Wear appropriate protective gear:Gloves, lab coats, and safety glasses should be worn to protect against steam and potential hazards.

- Avoid overfilling the chamber:Overcrowding the chamber can impede steam circulation and result in ineffective sterilization.

- Handle hot materials carefully:Materials removed from the autoclave are extremely hot and should be handled with caution.

- Dispose of contaminated materials properly:Contaminated materials should be disposed of according to established protocols to prevent the spread of infection.

FAQs

What are the key components of an autoclave?

The key components of an autoclave include the chamber, lid, pressure gauge, safety valve, and steam generator.

How do I operate an autoclave safely?

To operate an autoclave safely, wear appropriate protective gear, avoid overfilling the chamber, handle hot materials carefully, and dispose of contaminated materials properly.

What are some common autoclave problems and how can I troubleshoot them?

Common autoclave problems include failure to reach sterilization temperature, steam leaks, pressure fluctuations, and error messages. Troubleshooting involves identifying the root cause and implementing appropriate solutions.